Stretch-release Tape (Bond & Detach®)

Tesa Bond & Detach® is an extraordinary adhesive technology used for demanding bonding applications that provides the option to be removed residue-free by stretching. The unique and patented technology was developed by tesa and offers the possibility of simple and secure reworkability during the entire product lifecycle – from production to end of life.

|

Product group | tesa® 76555 | Technical data | ||

| Backing material | None | Peel adhesion | Steel (inital) | 30 N/cm | |

| Type of adhesive | Specialty | PE (initial) | 13 N/cm | ||

| Color | White | Elongation at break | 700 % | ||

| Thickness | 500 μm | Temperature resistance (long term) |

90 °C | ||

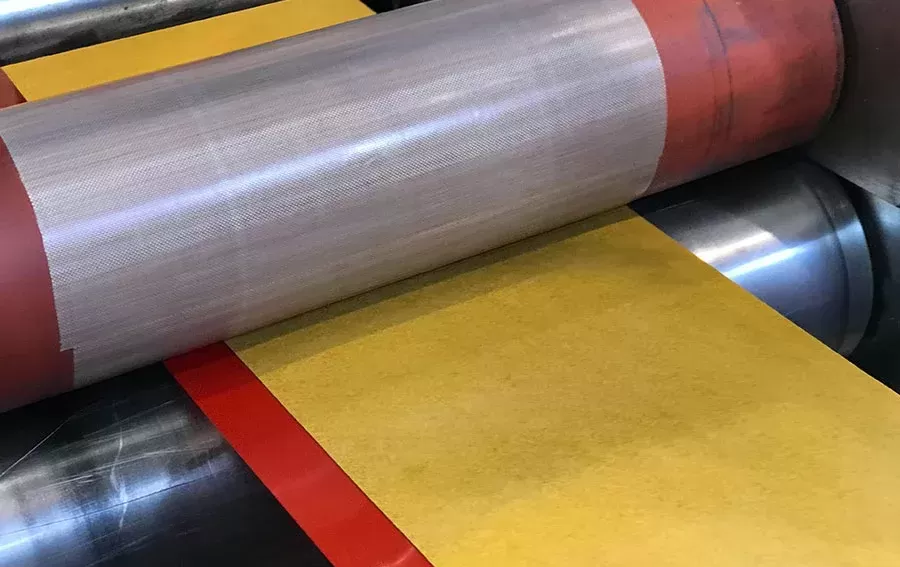

Heat Activated Film (HAF®)

tesa HAF® is a thermosetting adhesive system, provides high structural bonding performance to a wide variety of substrates. An irreversible cross-linking reaction is initiated by heat and pressure starting at temperatures above 120°C, resulting in extremely strong bonds. The processing of these adhesive systems is simplified due to excellent die cuttability, immediate handling stability after activation, and low oozing.

|

Product group | tesa HAF® 94xx |  |

| Backing material | None | ||

| Type of adhesive | Nitrile rubber / phenolic resin |

||

| Color | Amber | ||

| Thickness variations | 30 μm: 9405 60 μm: 9410 125 μm: 9402 200 μm: 9401 |

Customized Solutions of Tesa Automotive Tapes

At TCA, we are committed to delivering high-quality, customized solutions that meet the unique requirements of our clients in the automotive industry. Partner with us for reliable and efficient solutions that drive success in your projects.

Optically Clear Adhesive (OCA)

| Product group | tesa® 887xx | tesa® 880xx | tesa® 699xx |

|

|

|

|

| Backing material | None | None | None |

| Type of adhesive | Acrylic | Acrylic | Acrylicv |

| Category | PSA | PSA | UV cure |

| Color | Transparent | Transparent | Transparent |

| Key characteristics | Superior gap compensation performance of glass covers in a thickness range up to 500μm |

Best in class outgassing avoidance to enable optical integration behind plastic covers |

UV cure feature enabling good ink step coverage and special curing through PC option |

| Focus application | Glass substrate, L-size, Curved | Plastic substrate | Plastic curved display |

| Thickness variation | 200 μm: 88708 250 μm: 88710 300 μm: 88712 500 μm: 88720 |

150 μm: 88006 200 μm: 88008 250 μm: 88010 300 μm: 88012 |

50 μm: 69902 100 μm: 69904 150 μm: 69906 200 μm: 69908 |

| Reference product | 88708 | 88008 | 69908 |

| Thickness | 200 μm | 200 μm | 200 μm |

| Peel adhesion* (Glass) | 8.2 N/cm | 7.6 N/cm | 14.5 N/cm |

| Peel adhesion* (PC) | — | 7.1 N/cm | 14.9 N/cm |

| Transmittance (380 – 780nm) > |

99.5 % | 99 % | 99 % |

| Refractive index | 1.48 | 1.47 | 1.48 |

| Ink step coverage | ••• | •• | ••• |

| Outgassing resistance | • | •••• | •••• |

| Curved application | •••• | ••• | •••• |