Attachment part mounting with tesa® ACXplus

Bonding power

tesa® ACXplus creates a powerful bond even between materials with different surface characteristics, such as automotive attachment parts and clear coats. It ensures:

tesa® ACXplus creates a powerful bond even between materials with different surface characteristics, such as automotive attachment parts and clear coats. It ensures:

• Reliable bond on clear coat and other vehicle parts even after short dwelling time

• Securing of the parts‘ edges against lifting

• Very high reliability throughout the vehicle‘s lifetime

• Design flexibility with limited bonding area

Stress dissipation

During the lifetime of a vehicle, static and dynamic stress act upon the constructive bond between the car body and the attachment part. These can be caused by different thermal elongation of the respective substrates. Due to the viscoelastic behavior of tesa® ACXplus, the stress can be optimally dissipated, and a secure bond is assured even during extreme temperature changes.

During the lifetime of a vehicle, static and dynamic stress act upon the constructive bond between the car body and the attachment part. These can be caused by different thermal elongation of the respective substrates. Due to the viscoelastic behavior of tesa® ACXplus, the stress can be optimally dissipated, and a secure bond is assured even during extreme temperature changes.

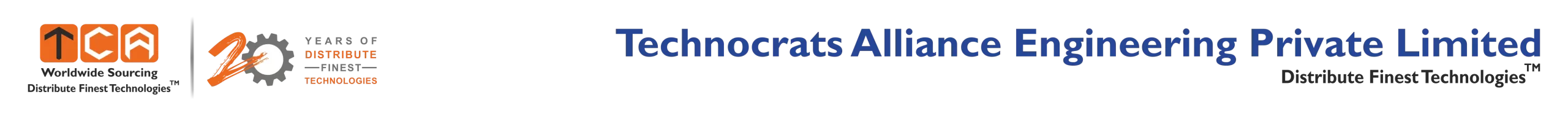

Unique conformability

With the high comformability of tesa® ACXplus, it is applicable in curves and corners without lifting of the liner. In addition, minor surface irregularities of the parts bonded together can be compensated for, so that a maximum adhesion surface is achieved for a long-lasting bond.

With the high comformability of tesa® ACXplus, it is applicable in curves and corners without lifting of the liner. In addition, minor surface irregularities of the parts bonded together can be compensated for, so that a maximum adhesion surface is achieved for a long-lasting bond.

Customized Solutions of Tesa Automotive Tapes

At TCA, we are committed to delivering high-quality, customized solutions that meet the unique requirements of our clients in the automotive industry. Partner with us for reliable and efficient solutions that drive success in your projects.

Tesa® ACXplus – Acrylic Foam Tape

| Product series | 772xx Base Line |

78xx Black Line |

771xx | 776xx Primerless |

777xx Primerless |

778xx Primerless |

||

|

|

|

|

|

|

|||

| Backing material | Soft acrylic foam | Foamed acrylic | Soft acrylic foam | Soft acrylic foam | Soft acrylic foam | Soft acrylic foam | ||

| Type of adhesive | Open side | Pure acrylic | Modified acrylic | Tackified acrylic | Pure acrylic | LSE | LSE | |

| Covered side | Pure acrylic | Modified acrylic | Tackified acrylic | LSE | Pure acrylic | LSE | ||

| Color | Gray | Deep black | Black | Gray | Gray | Gray | ||

| Thickness variations | 400 μm: 77204 600 μm: 77206 800 μm: 77208 1000 μm: 77201 1200 μm: 77202 |

500 μm: 7805 800 μm: 7808 1100 μm: 7811 1200 μm: 7812 1500 μm: 7815 2000 μm: 7820 |

800 μm: 77108 1200 μm: 77112 1500 μm: 77115 |

800 μm: 77608 1100 μm: 77611 1500 μm: 77615 |

800 μm: 77708 1100 μm: 77711 1500 μm: 77715 |

500 μm: 77805 800 μm: 77808 1100 μm: 77811 1500 μm: 77815 |

||

| Reference product | tesa® 77212 | tesa® 7811 | tesa® 77112 | tesa® 77611 | tesa® 77711 | tesa® 77811 | ||

| Thickness | 1200 μm | 1100 μm | 1200 μm | 1100 μm | 1100 μm | 1100 μm | ||

| 90° peel adhesion* | ASTM Steel | Open side |

32 N/cm* | 33 N/cm* | 30 N/cm* | 41 N/cm* | 33 N/cm* | 35 N/cm* |

| ABS | Open side |

12 N/cm* | 35 N/cm* | 25 N/cm* | 12 N/cm* | 36 N/cm* | 31 N/cm* | |

| MSE clearcoat (polar)** |

Covered side |

31 N/cm* | 28 N/cm* | 30 N/cm* | 36 N/cm* | 32 N/cm* | 39 N/cm* | |

| LSE clearcoat (un-polar)*** |

Covered side |

27 N/cm* | 32 N/cm* | 27 N/cm* | 44 N/cm* | 30 N/cm* | 45 N/cm* | |

| Dynamic shear resistance* |

PP/EPDM and MSE clearcoart**** |

Open side |

79 N/cm* | 69 N/cm* | 81 N/cm* | 84 N/cm* | 68 N/cm* | 71 N/cm* |

| PP/EPDM and MSE clearcoart**** |

Covered side |

38 N/cm** | 19 N/cm** | 35 N/cm** | 20 N/cm** | 27 N/cm** | 24 N/cm** | |

| Temperature resistance***** |

Short term (15 min.) | 120 °C | 120 °C | 120 °C | 120 °C | 120 °C | 120 °C | |

| Long term (3 months) | 80 °C | 80 °C | 80 °C | 80 °C | 80 °C | 80 °C | ||

| * 3 days | ** MSE = medium surface energy | *** LSE = low surface energy | **** Pre-treatment of PP/EPDM side except for 77811/77711 ***** Static shear tests. Displayed values are target values, values can differ by customer substrates, load and test method. * RT | ** 80°C |

||||||||

PE Foam Tape

| Product group | tesa® 66108 | tesa® 6285x / 62708 | tesa® 6290x | tesa® 649xx | |

|

|

|

|

||

| Backing material | PE foam | PE foam | PE foam | Soft acrylic foam | |

| Type of adhesive | Tackified acrylic | Pure acrylic | Acrylic | LSE | |

| Color | Black | Black | Black | Black | |

| Key characteristics | General purpose | High temperature performance |

High initial performance | Primerless | |

| Thickness variations | 800 μm: 66108 | 500 μm: 62852 800 μm: 62708 900 μm: 62855 1200 μm: 62856 |

400 μm: 62904 600 μm: 62906 |

500 μm: 64905 800 μm: 64908 1200 μm: 64912 |

|

| Reference product | tesa® 66108 | tesa® 62708 | tesa® 60906 | tesa® 64908 | |

| Thickness | 800 μm | 800 μm | 600 μm | 800 μm | |

| 90° peel adhesion* | ASTM Steel | 10 N/cm* | 15 N/cm* | 19 N/cm* | 19 N/cm* |

| ABS | 10 N/cm* | 15 N/cm* | 19 N/cm* | —— | |

| PP | 10 N/cm* | —– | —— | 19 N/cm* | |

| Tensile strength | 8 N/cm* | 18 N/cm* | 11 N/cm* | 8 N/cm* | |

| Temperature resistance** |

Short term (15 min.) | 80 °C | 120 °C | 110 °C | 80 °C |

| Long term (3 months) | 80 °C | 100 °C | 100 °C | 80 °C | |

| * 14 days | ** Static shear tests. Displayed values are target values, values can differ by customer substrates, load and test method. * RT | |||||

High-initial Performance Tape (HiP)

|

Product group | tesa® 92xxx HiP | tesa® 92108 HiP / 800 μm | ||

| Backing material | None | 90° Peel adhesion | Steel (inital) | 32 N/cm | |

| Type of adhesive | High performance polymer foam | Steel (3 days) | 35 N/cm | ||

| Color | Black | PP (initial) | 28 N/cm | ||

| Thickness variations | 500 μm: 92105 800 μm: 92108 1100 μm: 92111 |

pp (3 days) | 36 N/cm | ||

Sealing Tape for Slush Skin (Single-sided Tape)

|

Product group | tesa® 50340 | tesa® 92108 HiP / 800 μm | ||

| Backing material | PU film | 90° Peel adhesion | Steel (inital) | 32 N/cm | |

| Type of adhesive | Acrylic | Steel (3 days) | 35 N/cm | ||

| Color | Transparent | PP (initial) | 28 N/cm | ||

| Thickness variations | 105 μm | pp (3 days) | 36 N/cm | ||

tesa® ACXplus Seal Line – Acrylic Foam Tape for Seal Mounting

|

Product group | tesa® ACXplus 745xx Seal Line | tesa® ACXplus 74508 Seal Line / 800 μm | |||

| Backing material | Foamed acrylic | 90° Peel adhesion | Glass (1 day) | 32 N/cm | ||

| Type of adhesive | Open side | Acrylic | Glass (10 days, warm / humid*) |

35 N/cm | ||

| Covered side | Heat-activatable | T-Peel test | TPE (1 day) | 35 N/cm | ||

| Color | Deep black | TPE (10 days, warm / humid*) |

28 N/cm | |||

| Thickness variations | 800 μm: 74508 1200 μm: 74512 |

|||||