Daikin Proportional valves/Servo valves

Features

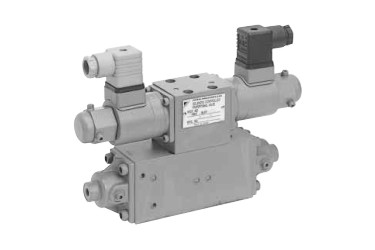

- Proportional throttle switching valve to carry out feed-back control of spool position by detecting the variation of the spool with a differential transformer, as the proportional solenoid directly drives the spool.

- A combination of a pressure compensation valve and an exclusive driver makes it possible to create a proportional flow control in high accuracy.

- LEMS valve is stack type one and can carry out the T port ‘s meter-out control in a proportional flow control system in high accuracy by means of attaching stack under a solenoid operated valve in combination of an exclusive reducing type pressure compensation valve.

Features

- The valve switching four directions enables the control of the actuator’s round process.

- This valve itself can be used for a shock-less switching valve.

- With a differential transformer

- A proportional solenoid directly drives a spool and detects the variation of the position, carrying out a feed back control for the spool position.

- The combination of a pressure compensation valve and an exclusive driver makes it possible to do a proportional flow control in high accuracy.

- Without differential transformer

- Mounts an exclusive driver (ZDN-2-10).

- The combination with a pressure compensation valve enables it to use as an easy type flow control valve.

Features

- In combination with exclusive driver, it can have a high response and suits the closed loop controls of position , speed and pressure for a main machine’s actuator. (Frequency response: 130Hz/-3dB±10% amplitude)

- Since a proportional solenoid directly drives a spool, the leak volume can keep a least value compared to a nozzle flapper type servo valve.

- When an exclusive driver is used, it becomes all port block (fail safefunction) at power off.

Features

- Suits a closed loop control of position, speed and pressure of main machine’s actuator.

- As a pilot valve adopts large sized orifice nozzle for a nozzle flapper type,anti-contaminant characteristics is strengthen.

- A driver is mounted on a valve.

- As option with pressure sensor is provided, closed loop control can be easily performed.

Features

- A stack type control valve with proportional flow characteristics of a pressure compensation type. The current and flow rate are proportional in spite of the load size.

- Possible to make a structure of a power-much circuit outputting the required pressure and flow rate in combination of variable volume type pumps.

- Possible to control the flow rate at A port and B port individually.

- As assembled in the order of an inlet valve block and a solenoid proportional valve, each valve block is mounted on a manifold block. The manifold block and sub-block are separated by every valve, and tightened with the through bolts together with the end plate corresponding to the required switching valve’s linkage number (Max. eight links).—(Block-built system).

Features

- Controls a solenoid proportional control valve of a open loop control system to an optimum condition.

- Owing to the constant-current characteristics, the variations of supply voltage and of output current by a solenoid temperature rise rarely happen.

- The output radio wave corrugation (dither frequency , amplitude) is set up so that hysteresis of a solenoid proportional control valve and a resolution power can get the best values.

- Since the current is controlled by PWM(pulse width modulation) method, heat generation from driver is restrained to be the smallest.

- As the function (response time adjusting function) to vary the output current slowly for the variation of step like command input is provided, it enables the oil output to vary in shock-less. (for either build-up or pull-down process, each process can be independently adjusted).

Features

- Controls a solenoid proportional control valve of a open loop control system to an optimum condition.

- Owing to the constant-current characteristics, the variations of supply voltage and of output current by a solenoid temperature rise rarely happen.

- The output radio wave corrugation (dither frequency , amplitude) is set up so that hysteresis of a solenoid proportional control valve and a resolution power can get the best values.

- Since the current is controlled by PWM (pulse width modulation) method, heat generation from driver is restrained to be the smallest.

- As the function (response time adjusting function) to vary the output current slowly for the variation of step like command input is provided, it enables the oil output to vary in shock-less. (for either build-up or pull-down process, each process can be independently adjusted).

Features

- Controls LEM* valve which detects the spool position by a differential transformer to carry out a feed back control (minor feed back).

- Owing to the constant-current characteristics, the variations of supply voltage and of output current by a solenoid temperature rise rarely happen.

- The output radio wave corrugation (dither frequency , amplitude) is set up so that hysteresis of a solenoid proportional control valve and a resolution power can get the best values.

- Since the current is controlled by PWM (pulse width modulation) method, heat generation from driver is restrained to be the smallest.

Features

- Controls KSP-G02 in optimum conditions.

- Owing to the constant-current characteristics, the variations of supply voltage and of output current by a solenoid temperature rise rarely happen.

- The output radio wave corrugation (dither frequency , amplitude) is set up so that hysteresis of a solenoid proportional control valve and a resolution power can get the best values.

- Since the current is controlled by PWM (pulse width modulation) method, heat generation from driver is restrained to be the smallest.

- As the function (response time adjusting function) to vary the output current slowly for the variation of step like command input is provided, it enables the oil output to vary in shock-less. (for either build-up or pull-down process, each process can be independently adjusted).

Features

- Controls KSP valve of an open loop control system to optimum conditions.

- Owing to the constant-current characteristics, the variations of supply voltage and of output current by a solenoid temperature rise rarely happen.

- The output radio wave corrugation (dither frequency, amplitude) is set up so that hysteresis of a solenoid proportional control valve and a resolution power can get the best values.

- Since the current is controlled by PWM (pulse width modulation) method, heat generation from driver is restrained to be the smallest.

- As the function (response time adjusting function) to vary the output current slowly for the variation of step like command input is provided, it enables the oil output to vary in shock-less. (for either build-up or pull-down process, each process can be independently adjusted).

Features

- Controls LEM valve which detects the spool position by a differential transformer to carry out a feed back control (minor feed back).

- Owing to the constant-current characteristics, the variations of supply voltage and of output current by a solenoid temperature rise rarely happen.

- The output radio wave corrugation (dither frequency , amplitude) is set up so that hysteresis of a solenoid proportional control valve and a resolution power can get the best values.

- Since the current is controlled by PWM (pulse width modulation) method, heat generation from driver is restrained to be the smallest.

- As the function (response time adjusting function) to vary the output current slowly for the variation of step like command input is provided, it enables the oil output to vary in shock-less. (for either build-up or pull-down process, each process can be independently adjusted).